Rebar Detailing Services

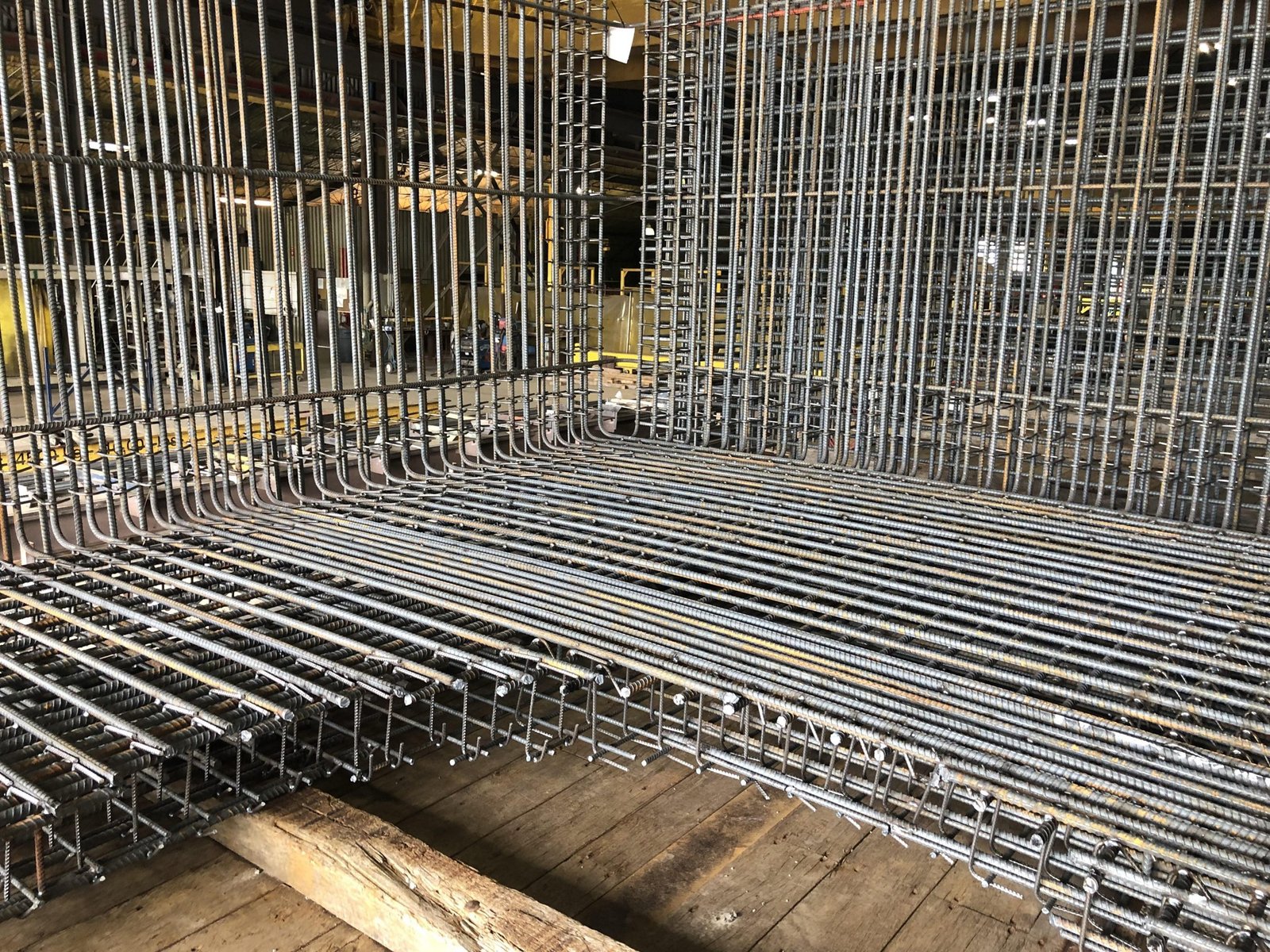

With industry leading expertise in estimating, detailing, and modeling of complex reinforced concrete construction projects, Square D plays a pivotal role in helping move projects from the design phase to the construction phase. Having successfully delivered iconic projects globally in various sectors around the world, you can confidently partner with us to support all your reinforced concrete modeling, detailing, and estimating needs.

Supplemented by stringent QA/QC procedures, we can help eliminate field placement errors, while allowing information transfer among project stakeholders to help validate project details. This results in reduced issues, so rebar fabrication and assembly can be expedited with fewer changes in field.

What We Do

2D Rebar Detailing

Our drawings provide ironworkers and steel fixers in the field with easy-to-read blueprints for the placement of reinforcing bars.

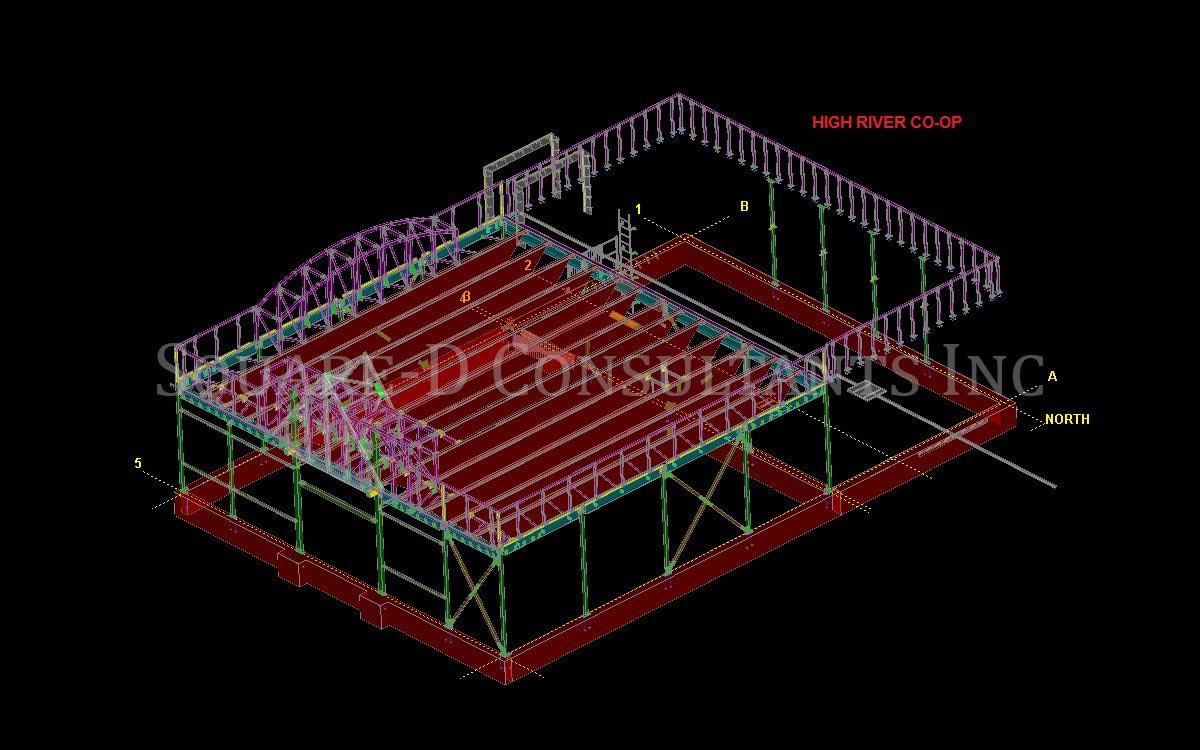

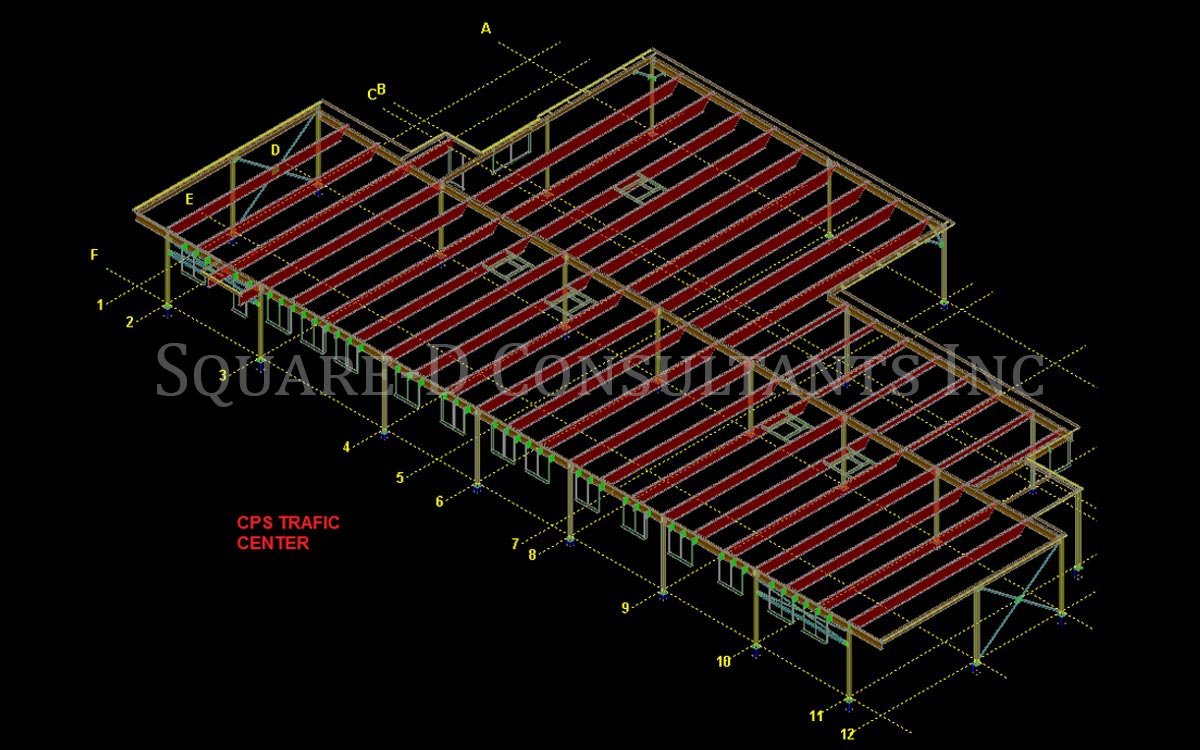

3D Rebar Modeling

Our drawings provide ironworkers and steel fixers in the field with easy-to-read blueprints for the placement of reinforcing bars.

Rebar Detailing Estimation

Our drawings provide ironworkers and steel fixers in the field with easy-to-read blueprints for the placement of reinforcing bars.

3D Rebar modeling

Our 3D concrete and rebar modeling integrates data for on and off-site planning, procurement, fabrication and erection of concrete and rebar for all types of projects. By introducing rebar detailing early in the design phase of your project, Square D can ensure the predictability and accuracy of the drawings and shop-bar ready lists. Better visualization and collaboration means fewer revisions and mitigated risks due to fewer unknowns, and a faster construction time due to less field coordination and downtime.

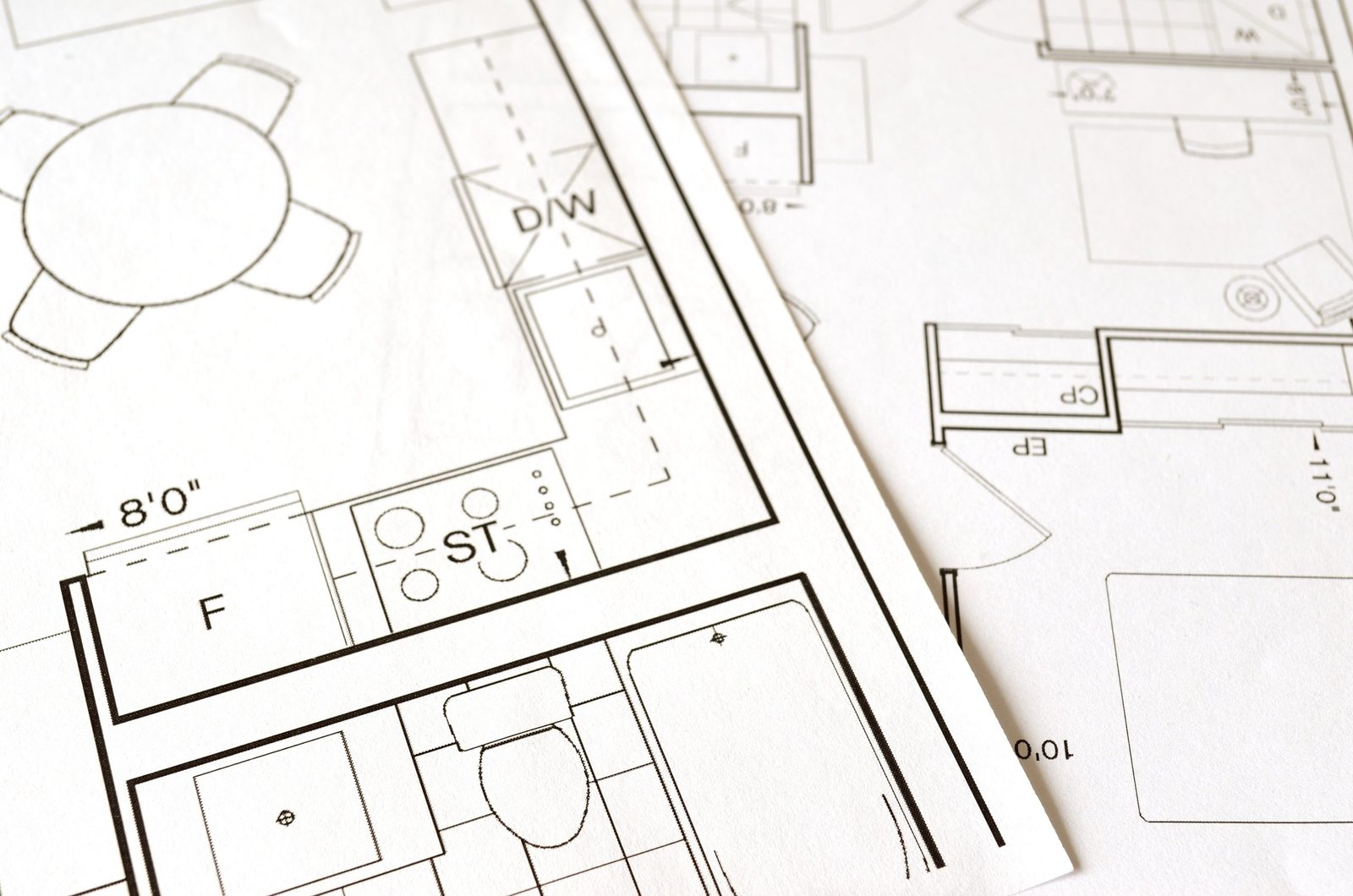

2D Rebar Detailing

Our comprehensive rebar field placement and shop drawings include all information necessary for complete fabrication, ordering and placing of all reinforcing steel, bar support systems, and accessories. Our drawings provide ironworkers and steel fixers in the field with easy-to-read blueprints for the placement of reinforcing bars. Our accurate bar listing and bending schedules facilitate simplified shop fabrication and helps to reduce scrap material.

2d rebar detailing

Our comprehensive rebar field placement and shop drawings include all information necessary for complete fabrication, ordering and placing of all reinforcing steel, bar support systems, and accessories. Our drawings provide ironworkers and steel fixers in the field with easy-to-read blueprints for the placement of reinforcing bars. Our accurate bar listing and bending schedules facilitate simplified shop fabrication and helps to reduce scrap material.

rebar estimating

With the capacity to estimate large tonnages of rebar, our clients have come to rely on our timely and accurate data. Our comprehensive, bar-by-bar quantity take-offs provide detailed, accurate quotes for placing successful bids. On on-going jobs, our experienced estimating team has ability to provide actual detailed versus estimate weight tracking, along with in-depth change order and variation reviews.

Our placing drawings help in Fabrication and allow placing to be done cost effectively,leading to the completion of the constructions without any delay.

Easy to understand

Each sheet is designed separately with unique bar bending schedule in the same sheet, helping the placer to work without difficulty. Enough cross-sections and enlarged details are taken at congested locations.

Fabrication and placer friendly

All unconfined bars are grouped to reduce the bar marks in a placer friendly way, making it easy for fabrication.

Three-level checking process

#1 SELF CHECKING

#2 QUALITY CONTROL

#3 PROJECT MANAGER REVIEW

The drawings are reviewed by the Detailing Engineer who is handling the project. All the corrections are done before it goes to the next level i.e., Quality Control.

The drawings are reviewed by an experienced team leader to make sure all the details from the contract drawings are followed and ensure that each standard specified by the client is met. Then the drawings are sent to the review of Project Manager.

This is the last and final review, where the project manager thoroughly checks the drawing from the aspects of Fabrication and Placing.

Bar Listings

Our bar listings are available in the following formats: ASA, Soule (SLE), Pinnacle (PIN), Romac (ROM), Canada Wide (WID), ARMA+(CSF), Shear 97, RMS(CDI) and TSV.

Material list separation

Avoid light load charges

Patch lists

The bar lists are submitted seven to ten days before the set delivery date or the date mentioned by the Fabricator whichever is earlier.

Our Works